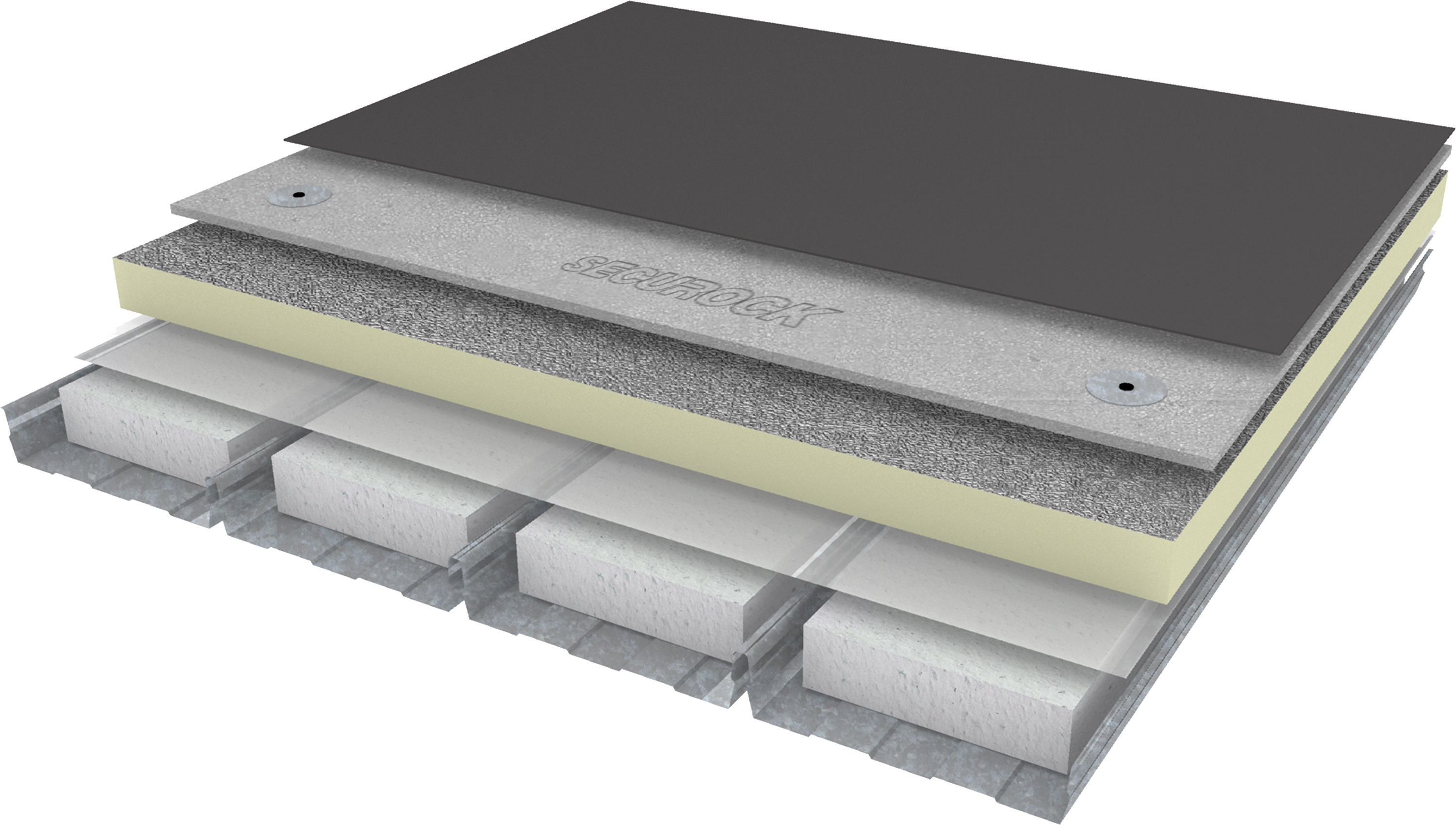

Securock cement roof board ideal for use as a cover board in system applications such as liquid applied membranes or as a parapet fire or thermal barrier roof board lightest cement board in the industry environmentally sustainable product lower weight reduces embodied energy and embodied emissions.

Securock cement roof board.

It is designed to enhance the entire roofing system as both a cover board and as a parapet fire or thermal barrier roof board.

The specially treated core and high performance glass mat facer provide protection against fire mold and moisture while high quality mat produces less itchiness than competitive products.

Usg securock brand gypsum fiber roof board is a high performance roof board for use in low slope roofing systems.

Plus because it is cement based it provides superior compressive strength water durability and mold resistance and will not rot warp delaminate or disintegrate in the presence of water.

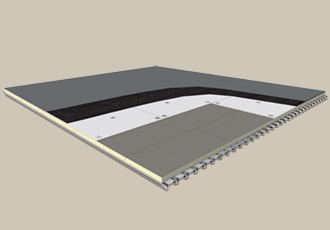

Securock cement roof board is a high performance roof board for use in low slope roofing systems.

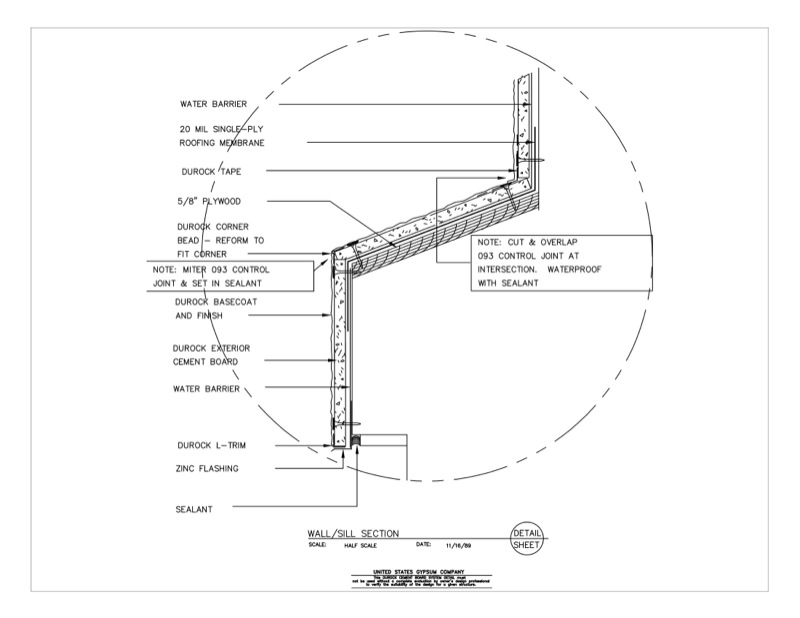

As a parapet fire or thermal barrier roof board securock cement roof board has an unlimited slope classification and is noncombustible.

Securock brand ultralight glass mat roof board is a high performance roof board for use in low slope commercial roofing systems.

The board is formed using an aggregated portland cement slurry with a polymer coated glass fiber mesh completely encompassing edges and both surfaces to enhance bond strength of membrane systems and gives excellent resistance to delamination.

The lightest cement board in the industry securock brand cement roof board is easy to handle cut and fasten.

The sustainable design has earned independent certification from scientific certification systems.

Its unique fiber reinforced homogeneous composition gives the panel strength and water resistance through to the core.

Securock brand gypsum fiber roof board s dense concentration of gypsum and cellulose fibers provides exceptional panel and bond strength low surface absorption and superior wind uplift performance with no face layer to delaminate.

The board is formed using an aggregated portland cement slurry with a polymer coated glass fiber mesh completely encompassing edges and both surfaces to enhance bond strength of membrane systems and gives excellent resistance to delamination.